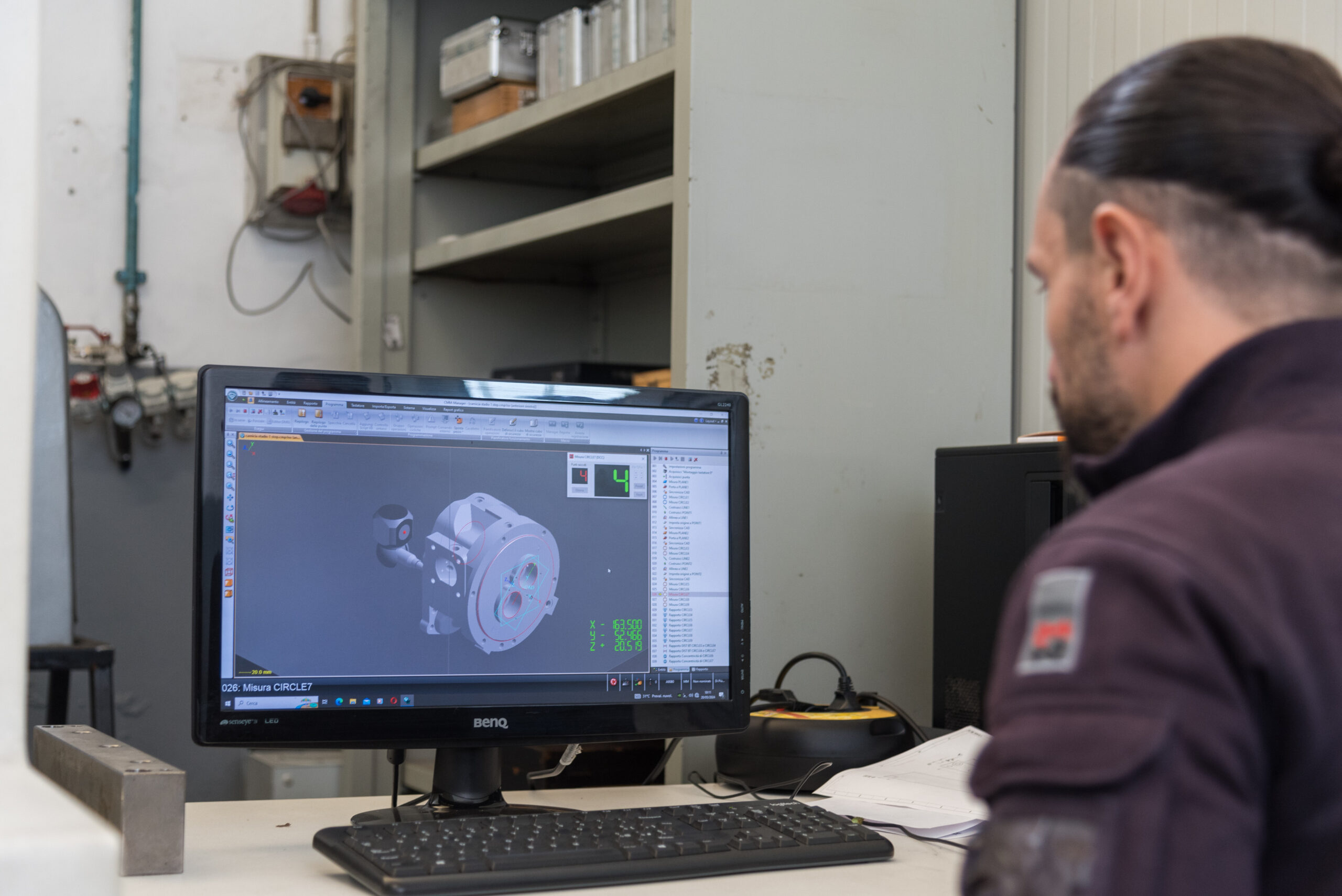

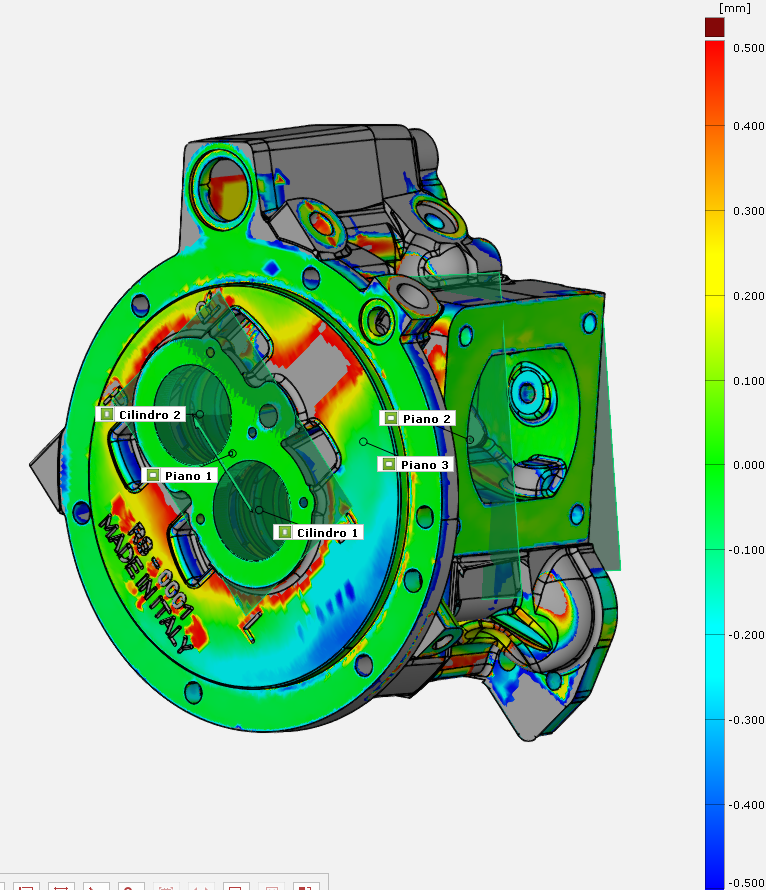

Riem Italy uses technologically-advanced instruments to develop the

reverse engineering process, studying the shape and dimensions of the

items to be reproduced using specific analysis and 3D scanning processes.

This process is also carried out during the production phase.

After that, these data are inserted in a specific software for CNC

(Computer Numerical Control) machines to reproduce the required

parts. The manufactured components are accompanied by certification

that guarantees the machining processes and the chemical composition

of the material.

At the customer’s request, we design the spare part to be manufactured and, if necessary, we produce the mold to be sent to our trusted foundry, which will provide us with the raw casting.

Upon arrival from the foundry, the raw part is machined using our own machine tools.

Our products are branded RIEM Italy, which highlights the fact that they stem from a reverse engineering process that has positioned us in the international market for years as a brand known for both reliability and a fair quality/price ratio.