Compressor Networks: Why and How to Create Them

Marzo 1, 2017

Compressor Networks

One of the first factors to consider when designing Compressor Networks is the maximum operating pressure at which the system must work, which varies between 4 and 6 bar.

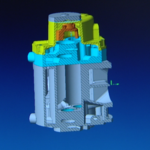

Depending on the flow rate, you can choose between a reciprocating compressor for a flow rate of less than 0.3 Nm3/min, while for a flow rate of 0.5 to 50 m3/min, screw technology is recommended.

If you need to increase the flow rate, you can combine compressors in a lead-legs configuration or, better still, consider using centrifugal compressors.

Depending on the application, the compressed air must comply with the characteristics indicated by the classes defined by ISO 8573-1.

The choice of treatment depends not only on the use of the air but also on the intention to keep the system perfectly clean, reducing the need for maintenance.

Sometimes it is necessary to install an oil-free compressor accompanied by adequate filtration.

Consequently, after choosing the compressor technology, it is necessary to decide on the relative dimensions, taking into account the required working pressure and the pressure drop induced by the system necessary to guarantee the required quantity.

It is important and extremely necessary to assess the sufficient flow rate for the system with the operation of other operating machines. It is also advisable to size the tanks in such a way as to ensure sufficient time for the reserve tank to intervene or for the operating machines to complete their work cycle with the aim of securing them and avoiding damage to people and work.

Once the flow rate required for the system has been determined, the sizing of the equipment can be evaluated.

Establishing the correct sizing is very important, as it has a significant impact on the initial cost of the compressor and, subsequently, on electricity consumption.

Once the size has been determined, it is advisable to take into account the temperature of the intake air, which, in silenced compressors, must be kept 10°C higher than the temperature recorded in the compressor room.

It should be noted that when sizing the system, it is important to remember that there may be expansions in production and, as a result, more compressed air may be required.