VpVision Base

Luglio 2, 2017

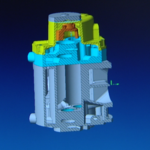

The measurement and control of parameters such as pressure, level, temperature, flow rate, and analysis is a key element in industrial processes. If these parameters are not taken into account, they can have a significant impact on the entire production chain as well as on costs. So how should we proceed? An effective solution is represented by the ‘VPVision Base’ model, offered by Innovative Instruments, the Italian market leader in the distribution of measurement and parameter control instruments. How does this new model work? It is presented as software as a service, but also offers a low initial investment (with small monthly fees), combined with advanced energy monitoring. To meet energy management needs, sensors and a precise data acquisition system are also installed on site. Let’s take the example of industries that use compressed air in their production departments. Compressed air circuits generally consist of a closed-loop network, and the various departments are closely interconnected. One of the most pressing needs in this case, precisely in order to optimize costs and reduce consumption, is to measure flow rate. In this case, the most suitable VPVsione Base solution is VPFlowScope, a software program that, once correctly installed (and for this reason, Innovative Instruments offers highly qualified technical and commercial staff), allows you to accurately determine the demand of each department, the demand for air in the network, and the direction of flow and reflux, leading to a significant improvement in consumption and related costs. VPFlowScope can interface with PCs, making its configuration and data reading extremely intuitive. Finally, there is a function that allows you to program the session to be recorded in advance and store the relevant data.