How a Centrifugal Compressor Works

Novembre 21, 2017

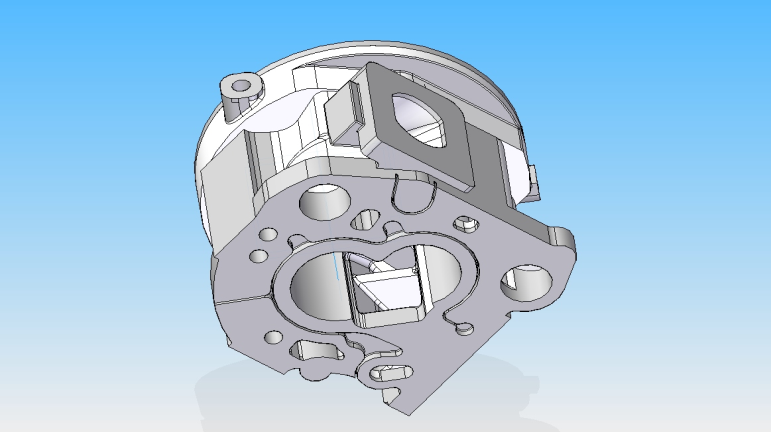

Let’s take a closer look at how a centrifugal compressor works, a machine that is widely used in industry and which Riem Italy deals with (both in terms of sales and maintenance). Let’s start by specifying that it is a turbomachine which, when used at maximum efficiency, can certainly help to save a considerable amount of energy. Let’s take a look at its complex mechanics: inside the centrifugal compressor, there is an impeller that supplies energy to a compressible fluid.

This operation serves to increase the pressure and is achieved through the use of diverging blades mounted on the impeller. In addition to this component, there is another very important one that also contributes to slowing down the air and thus transforming kinetic energy into pressure: the diffuser, which is also equipped with blades. Once this compression phase has been successfully completed, a collector takes over, whose purpose is to slow down the air and direct it to the next stage (or to the outside). It should be noted that centrifugal compressors are more complex machines than volumetric compressors.

The latter are usually more intuitive (and more commonly used), while centrifugal compressors exploit the laws of dynamic compression, which must necessarily be mastered by experts in the field in order to avoid unpleasant inconveniences that can affect the entire production process. It should be noted that machines such as centrifugal compressors require a consistent and continuous supply of air (all year round and 24 hours a day), so it is essential that the control of such systems is entrusted to trained and professional personnel. Riem Italy offers continuous assistance on centrifugal compressors, also providing maintenance and, in some cases, supplying damaged parts.