Centrifugal compressors: what they are and when to choose them

Novembre 24, 2020

Among the products offered by Riem Italy, a leading company in the production, maintenance, and distribution of industrial compressors, there are also new centrifugal compressors thanks to the partnership established with HANWHA POWER SYSTEM. In this article, we will take a closer look at what a centrifugal compressor is, what it is used for, and for which activities it is most suitable.

Why choose a centrifugal compressor?

This particular type of compressor is used in companies that need a large supply of compressed air. The machines consist of impellers designed specifically for each power range and have the advantage of being very reliable in terms of durability. Centrifugal compressors are used in various industrial sectors such as automotive, pharmaceutical, food, chemical, and renewable energy.

Why choose a centrifugal compressor? As mentioned, this type of compressor is ideal for those who need very high compressed air flows, so it should be recommended depending on the applications that customers need to use it for. They are also suitable for those who need to maintain stable, non-fluctuating flows. Unlike screw compressors, centrifugal compressors offer greater emission stability.

In many cases, centrifugal compressors are used in combination with screw compressors, with the former taking care of the base load and the latter managing the fluctuating upper load.

FURTHER INFORMATION: What is a screw compressor and how does it work?

How does a centrifugal compressor work?

Centrifugal compressors are also known as multistage compressors, because the pressure exerted on the air increases proportionally in different stages, reaching up to 13 bar.

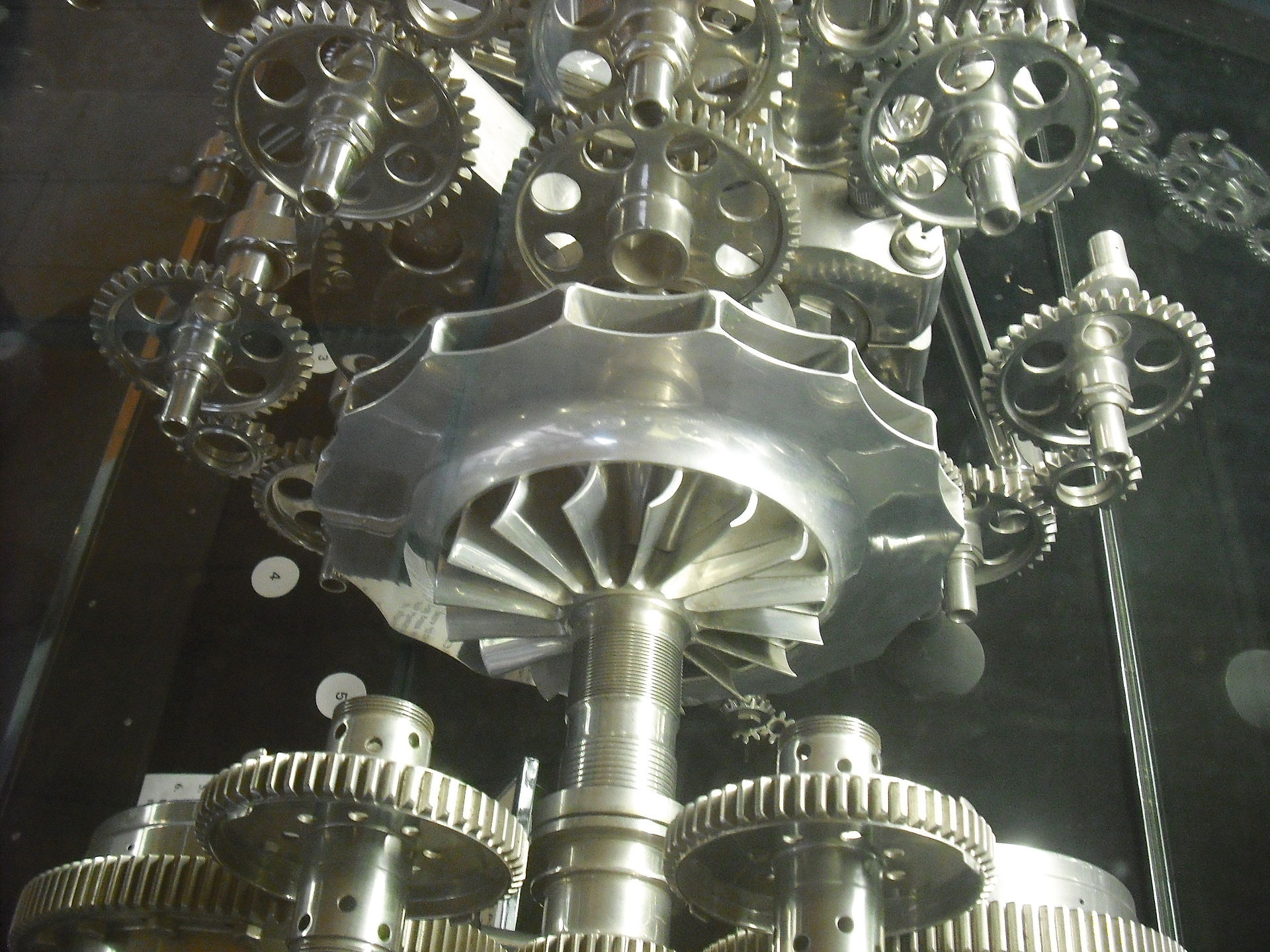

A centrifugal compressor consists of three main elements: the impeller, the diffuser, and the collector.

The impeller consists of a rotor disc with blades where the air flow enters. The blades can be located on one side of the disc or on both sides (in this case, it is called a double-entry impeller) and have the task of increasing the kinetic energy of the air.

The diffuser transforms the kinetic energy into static pressure.

The collector collects the air flow discharged by the diffuser and distributes it to the outlet pipe.

Types of Centrifugal Compressors

How many types of centrifugal compressors are there ? Clearly, each compressor can be optimized according to customer requirements. There are many possible configurations, but here are the three main ones:

- multi-stage axial centrifugal compressor: operates at low speed driven by induction motors. The blades are aligned axially one after the other and increase the pressure gradually

- turbo gears driven by induction motors that rotate at low speed and radial impellers that rotate at high speed

- high-speed radial turbo without gears. In this case, the motor directly drives the impeller.

Riem Italy distributes centrifugal compressors manufactured by HANWHA POWER SYSTEM, a world leader in the manufacture of centrifugal compressors and more. To find out more, VISIT OUR WEBSITE