Riem Italy Screw Compression Units

Gennaio 23, 2023

One of RIEM ITALY’s core activities is the construction and overhaul of compression units for oil-free and lubricated rotary screw air and gas compressors. These compressors belong to a group of industrial machines that are widely used in processing and transformation companies in various sectors (food, chemical, petrochemical, pharmaceutical, steel, automotive, etc.).

These machines are divided into single-stage and two-stage types. Single-stage machines (with a single compression unit) are used for low pressures up to 3.5 bar on the discharge side, while two-stage machines (with two compression units) operate with a maximum discharge pressure of 10 bar.

The machines are defined as oil-free or dry because there is no lubrication in the compression chamber.

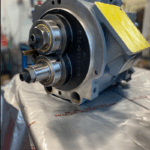

They are constructed from a cast iron casing, which includes a water- or oil-cooled jacket depending on the type of machine. The compression screws rotate inside the cylinder (casing) and, through their profiles, are able to draw in atmospheric air and compress it to the desired pressure.

Lubrication is present in the synchronizing gears, outside the compression chamber, and is circulated by a gear oil pump.

RIEM ITALY has developed its KNOW-HOW for the production and assembly of various components for the manufacture and overhaul of oil-free compression elements. During the zero-hour overhaul of oil-free screw units, the compression screws are replaced along with all rotating components, including bearings and synchronizing gears. This process makes the pump practically new.

It should be noted that RIEM ITALY holds the patent for the treatment of screws that have a fluoropolymer-based coating on their surface with anti-adhesive properties, and that the entire reconstruction process is subject to rigorous quality control, which concludes with a certified functional performance test which is provided to the customer as proof and guarantee of the quality of the work performed.

Of no less importance is the recovery of energy efficiency due to the ratio between the specific energy in KW and the MC delivered. It has been instrumentally found that this efficiency tends to decrease with increasing hours and modes of operation of the compressor, and for this reason it is considered advisable to monitor the two parameters (kw/mc).