Air Compressor Maintenance

Novembre 27, 2017

How important is compressor maintenance within a company’s economic system? We’ll tell you: extremely important! Although, at first glance, it might seem that the two things have nothing in common, they are in fact closely linked. In short, if plant and machinery maintenance is carried out properly and in strict compliance with the correct procedures, it can save the company a lot of money. But how is this possible?

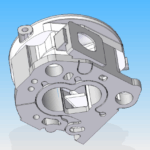

Let’s start with a consideration: first of all, it is essential to try to extend the operational life of a machine with the best tools, so as to justify the financial investment made at the time of purchase in the long term. Only in this way is it possible to recoup that investment economically. A centrifugal machine, for example, on which careful and continuous maintenance is carried out, certainly has a lot of potential to save money for the company that uses it, thereby earning more. As far as spare parts for centrifugal machines are concerned, we can distinguish between two categories: extraordinary maintenance and routine maintenance.

Routine maintenance involves all the work that the manufacturer considers necessary to keep the machine working properly. Extraordinary maintenance, on the other hand, includes all the work and activities needed to fix unexpected problems, like malfunctions and breakdowns. However, in addition to maintenance, in order for centrifugal machinery to function properly, it is necessary to rely on constant preventive assistance, aimed at replacing a component even if there are no obvious signs of damage. This preventive assistance operation fits perfectly into a cost-saving approach for companies that use centrifugal machinery and complements and supports the routine and extraordinary maintenance phases. In conclusion, and to get as complete a picture as possible, it is important to know that the maintenance costs of machinery are usually 20% of the total cost of that machinery.