Air treatment Lubricated compressors: Riem Italy’s professionalism

Marzo 7, 2023

The treatment of compressed air delivered to compressors is aimed at optimizing air quality.

The presence of condensation, consisting of water vapor mixed with oil vapor, which flows through the distribution lines to the various users, causes problems such as:

-corrosion of the internal surfaces of the pipes.

– reduced tool performance with increased maintenance costs.

– disturbances to control systems and related instrumentation.

-increased processing waste and, in frequent cases, production stoppages.

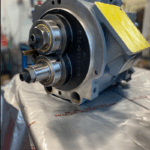

To contain and limit these effects, the condensate undergoes an initial water/oil separation treatment using an on-board centrifugal separator, which is normally fitted to a lubricated compressor.

Subsequent treatments are carried out in sequence by: line filters, from and in the compressed air storage tank, by the dryer equipped with pre- and post-filters.

Depending on the dew point to be achieved, the dryer can be a refrigeration cycle dryer or, for more extreme dew points, an adsorption dryer.

Another treatment that modern compressor rooms are equipped with is condensate treatment.

In fact, in the presence of lubricated compressors, the condensate contains traces of lubricating oil, which must be separated from the condensate through appropriate treatments. These will then be disposed of by specialized companies.

The brands of lubricated compressors and dryers represented by RIEM ITALY are: CECCATO, GARDNER DENVER, COMPAIR, CHAMPION, WORTHINGTON, and FRIULAIR.