Remove harmful substances from compressed air

Febbraio 18, 2021

We are back with a new article on utilities related tocompressed air. In this case, we will talk about contamination and, in particular, we will see how to remove harmful substances from compressed air in order to guarantee its quality and efficiency.

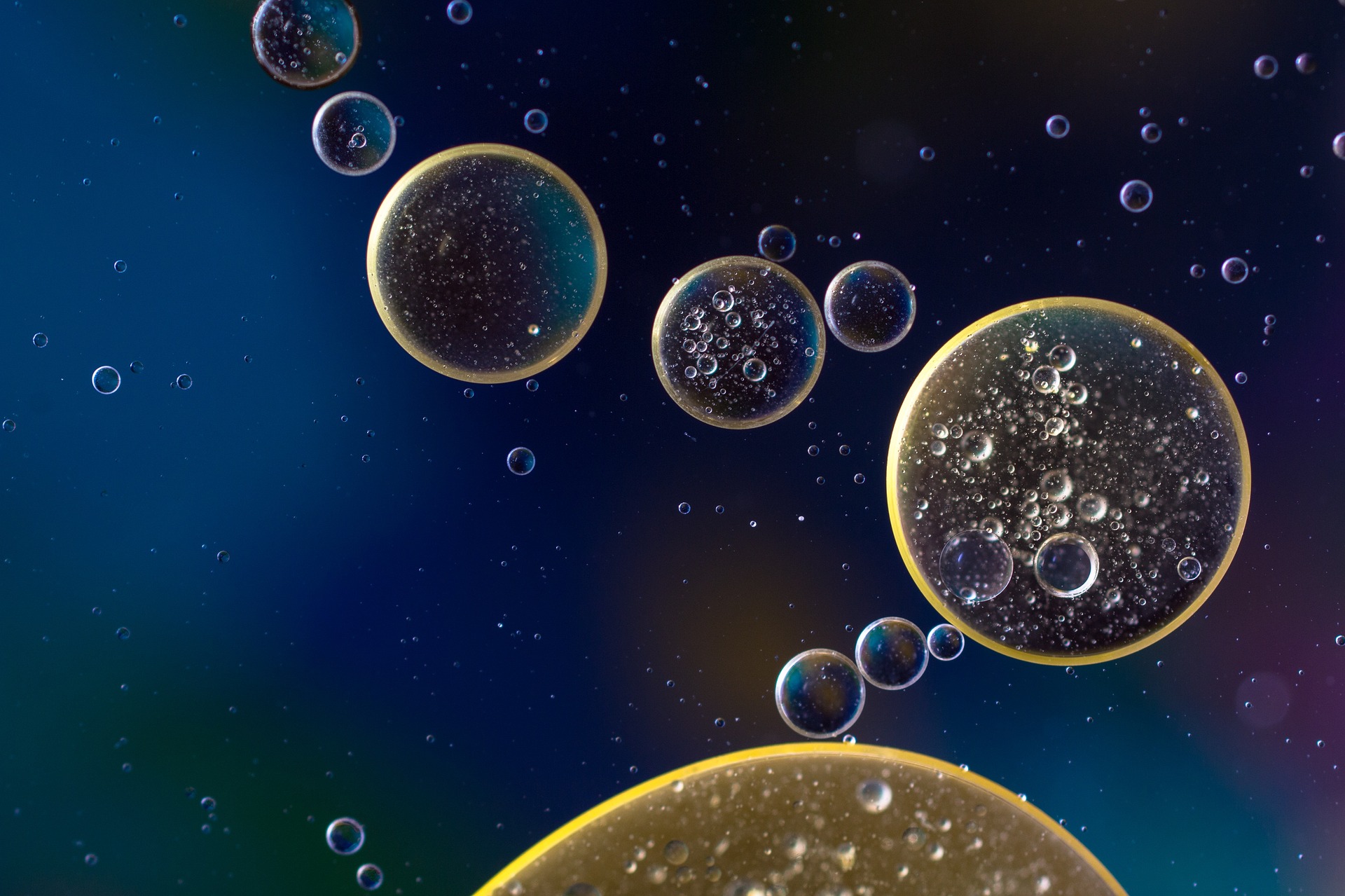

One of the factors that can contaminate the compressed air of a compressor is undoubtedly residual oil. In fact, despite the use of special filters, it is very difficult to know precisely how much oil remains in the compressed air after filtering. The high temperature does not allow for perfect separation of the elements, which means that traces of oil are not completely filtered out. Added to this is the ambient temperature itself, which can affect the temperature of a compressor in operation.

Removing harmful substances from compressed air: 3 recommended methods

To overcome this, one of the most commonly used methods is to keepthe air as dry as possible and prevent free water from damaging the fiber filters. These filters can only remove oil in liquid form (droplets) and cannot capture vapors, which must instead be removed with activated carbon filters. Using a combination of filters can be a good solution for oil contamination in compressed air. Clearly, the problem is reduced to zero if we replace our compressors with oil-free compressors, which do not require oil filters. This type of compressor operates at a lower delivery pressure but is excellent in terms of energy consumption, guaranteeing significant economic savings.

Riem Italy has been involved in oil-free compression for generations. If you would like to find out more, READ ALSO: Oil-Free Screw Unit Overhauls

Another method for removing harmful substances from compressed air involves the use of a final cooler capable of reducing the water content and lowering the temperature of the compressed air. Normally, the cooler is included in the system installation, downstream of the compressor, and is cooled by air or water.

The third method is to use a water separator to separate condensate from compressed air. The task of this separator is to remove as much condensate as possible once the air has been compressed. With proper adjustment, efficiency of up to 80%-90% can be achieved.