What a centrifugal compressor overhaul involves

Dicembre 19, 2017

How is a centrifugal compressor overhauled? And what solutions are available to avoid long periods of downtime during the overhaul?

Let’s start by saying that, in fact, the overhaul of large machines—such as centrifugal compressors —takes quite a long time, and this could translate into a financial loss for the company. Overhauling in the field is a job that must be planned very meticulously, requiring organization that must also include the costs of any spare parts, labor, various equipment, and finally, spaces large enough to allow service technicians to work safely. If the production chain stops, the company is the first to lose out.

A centrifugal compressor can last up to 40 years, provided that all the necessary checks and overhauls are carried out scrupulously. However, careful and scrupulous maintenance is not enough to prevent the centrifugal compressor from breaking down.

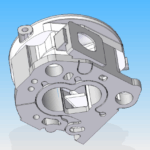

So what can be done? Through close collaboration between the manufacturer and users, alternative solutions can be found that primarily benefit productivity. One example is a technique called ‘Air-end Exchange’. What is it? In practice, it is an ‘exchange of the air-end’, i.e., only the part of the machine where the compression process takes place. During servicing, this component is replaced immediately, allowing the compressor machine to continue operating (to the benefit of productivity) while the rest of the machine is serviced (which, remember, can take from 2 to 4 weeks, depending on the size of the system). Ultimately, the ‘Air-end Exchange’ technique meets the needs of the company, as it significantly reduces downtime and helps to keep intervention costs low.