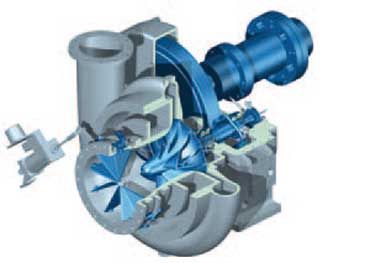

Centrifugal Compressor Spare Parts

Marzo 14, 2017

Spare parts for centrifuges

In the business economy, machine maintenance plays a fundamental role.

Obviously, it is essential to extend the operating life of a machine so that it can compete with rival machines.

Maintenance costs usually account for 20% of the total cost of the machinery.

Undoubtedly, for the end consumer, maintenance guarantees the operation and functionality of the machinery for several years, allowing a return on the financial investment made at the time of purchase.

Spare parts for centrifuges are divided into two different categories: routine maintenance and extraordinary maintenance.

Routine maintenance includes all activities deemed necessary by the manufacturer to prevent loss of functionality.

As a rule, the timing of interventions is planned based on the operating hours of the plant.

As for centrifugal compressors, their maintenance can be carried out by replacing the air and oil filter elements, which can cause significant damage if damaged or clogged.

Extraordinary maintenance deals with interventions related to unforeseen events such as breakdowns and anomalies, both preventively and reactively.

Preventive assistance can in turn be divided into preventive maintenance and predictive maintenance.

Preventive maintenance involves replacing a component in the absence of obvious damage.

Predictive maintenance involves analyses carried out on the monitoring of critical machine components.

Based on the results, it is possible to identify possible abnormalities in the operation of a specific element, allowing for timely intervention before further damage occurs.

Spare parts can be divided into three categories: consumable parts, ordinary spare parts, and critical spare parts.

Consumable parts are those parts of the machinery that wear out irreparably during operation of the system and must therefore be replaced periodically.

Ordinary spare parts are those parts that must be replaced when faults are detected and faults occur.

Critical spare parts are the fundamental parts of the machine designed with the intention of ensuring long machine productivity and a low probability of breakdown.

The manufacturer is responsible for compiling a list of recommended parts based on the characteristics of the machine.