Compressors and Batteries: How to Get the Best Out of Them

Aprile 11, 2017

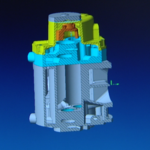

The problem that arises when optimizing flow rate becomes increasingly complex when multiple compressors are operating and supplying air to the same system.

To make it easier to distinguish between the many solutions and identify the most convenient one, there is a graphical system that allows you to correlate the capacity of the compressors and the required flow rate, so as to identify the critical conditions.

It is necessary to analyze the production process to determine whether the air demand is constant or variable.

If there is a variable air demand process, it is essential to identify the presence of cycles and their duration.

Air consumption must be quantified and measured in order to assign a precise demand value to any operating condition.

During the analysis, it is necessary to have specialized personnel with the necessary knowledge and equipment.

For each compressor installed, it is necessary to check the design performance and analyze the summer and winter conditions that determine the minimum and maximum flow rates achievable at full load, as well as the minimum and maximum extremes of the partialization range.

When performing this type of activity, it may be necessary to seek the support of the manufacturer, who has software capable of calculating the expected performance under different operating conditions for each machine.

Often, solutions that appear to be optimal are, after careful analysis, not optimal at all and present different problems in the initial study phase.

There is no single procedure for all machines because each case must be analyzed and studied professionally and methodically, involving both manufacturers and measurement experts.