Choosing the Right Compressor for Your Business

Novembre 9, 2020

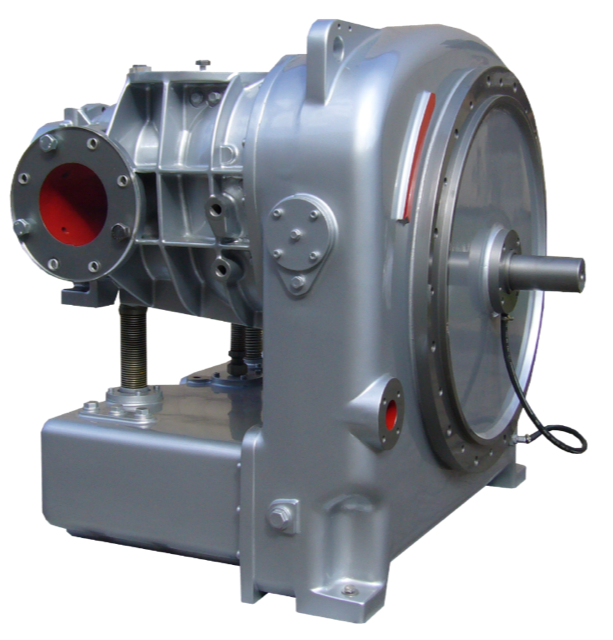

Compressors, as we all know, are not all the same. Just take a look at the products that Riem Italy manufactures and reconditions to understand how vast this sector is and how the most suitable compressor must be chosen for each specific situation. Oil-free or lubricated compressors? Which one to choose?

To answer this question, the first thing to ask is what process and application the compressed air is intended for. Before making a choice, it is necessary to understand the requirements and conditions of the system for which the compressor is intended. For example, in some cases, oil contamination is considered harmful, and for this reason, an oil-free compressor is chosen. Let’s take a general look at specific cases.

When to choose a lubricated compressor

Lubricated compressors are used by most small industrial workshops, with the exception of food production industries, where oil leaks could obviously cause contamination problems. But what is the purpose of compressor oil? Its role is fairly obvious, especially if we think of the word “lubricated.” Ultimately, oil is necessary for lubrication and sealing the compressor, as well as for cooling the compressed air. These particular types of compressors are widely used because they are less expensive than oil-free compressors and can still guarantee optimal purification of any oil leaks through the use of air products. For example, coalescing filters can be used, which are useful for cleaning compressed air, to which activated carbon filters can be added to achieve Class 1 air purity.

See products related to Riem Italy lubricated compressors: Lubricated machine maintenance

When to choose an oil-free compressor

As mentioned, oil-free compressors are mostly used for specific requirements, i.e. when the oil leaks typical of lubricated compressors can cause various problems for both products and people. Oil-free compressors are therefore ideal for the food, pharmaceutical, paper, and semiconductor industries.

Each of these compressors is labeled with certain indications that may seem similar, but are not: “Class 0” and “technically oil-free.” These two indications reveal the level of air purity following compression and follow the guidelines issued by the International Organization for Standardization (ISO). There are five air purity classes identified by ISO, each of which is quantified by measuring the number of particles per cubic meter.

Class 0 indicates the total absence of oil traces in the compressed air, therefore guaranteeing 100% oil-free air and is preferable to “technically oil-free” precisely because it meets more rigorous and absolute quality standards.

Discover the products related to Riem Italy oil-free compressors: Oil-Free Machine Maintenance Kit