Piston Compressors

Novembre 16, 2020

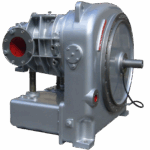

Riem Italy, a company specializing in the production and spare parts of industrial compressors, stands out on the market for its ability to offer highly professional and quality overhaul services. These include the overhaul of piston compressors. Today, let’s find out what a piston compressor is and why it is normally used.

The piston compressor: what is it?

To introduce the concept of a piston compressor, it is first necessary to understand the basic principles of air compression: volumetric compression and dynamic compression. In the first case, air is drawn into closed compression chambers and, as the volume of these chambers decreases, the air is compressed inside them. Once the desired compression ratio is reached, a valve is opened, allowing the air to be discharged into the outlet system. In the second case, the air is sucked in between the blades of a rotating impeller and accelerates until it reaches a high speed. Once the desired speed is reached, the air is discharged into the diffuser and the kinetic energy is transformed into static pressure. The piston compressor falls into the category of volumetric compressors, so the principle of volumetric air compression applies to it. The piston compressor is one of the most widely used in the industrial sector and, as we saw in our previous article, can be oil-free or lubricated.

READ ALSO: Which Compressor to Choose for Your Business

They can be configured in many different ways depending on their size and version. A piston compressor can be single or double acting and can have more or fewer cylinders.

A small compressor, for example, will have a V-shaped cylinder configuration, while in the case of medium-sized compressors, the cylinders are vertical. A large compressor, on the other hand, uses an L-shaped configuration with a vertical low-pressure cylinder and a horizontal high-pressure cylinder.

The most commonly used oil-free piston compressor is equipped with piston rings, generally made of reinforced Teflon, and larger compressors also have seals on the piston rods. Smaller machines, on the other hand, use sealed bearings.

Riem Italy’s piston compressor overhaul

Riem Italy overhauls zero-hour piston machines, both high and low pressure, lubricated or oil-free piston compressors. We also carry out maintenance thanks to a specialized technical service consisting of an experienced and qualified team. If some parts cannot be overhauled due to their state of wear, we take care of their complete reconstruction with new parts. Every overhaul comes with a one-year warranty.

FURTHER INFORMATION: Piston machine overhaul