Compressor terminology: dynamic and volumetric compression

Gennaio 13, 2021

Today we are launching a new column that will introduce us to the most important terms in the field of compression and compressors. In this article, we will focus in particular on the basic principles of air or gas compression, which are essentially two: volumetric compression and dynamic compression.

Volumetric compression includes all reciprocating, orbital, and rotary compressors: piston compressors, scroll compressors, screw compressors, cams, and vanes. Dynamic compression, on the other hand, includes axial and radial turbochargers.

Difference between the two types of compression: volumetric compression vs. dynamic compression

In volumetric compression, air or gas is drawn into several sealed compression chambers on the inlet side. As air or gas enters, the volume of the chambers gradually decreases, compressing the elements; when the desired compression value is reached, valves are activated to allow the air or gas to be discharged into the outlet system.

In dynamic compression, air or gas is sucked in by the blades of a rotating compression impeller that gradually increases its speed. Once high speed is reached, the elements are discharged by the diffuser, which transforms kinetic energy into static pressure. The compression ratio is given by the absolute pressure on the inlet and outlet sides of the air or gas.

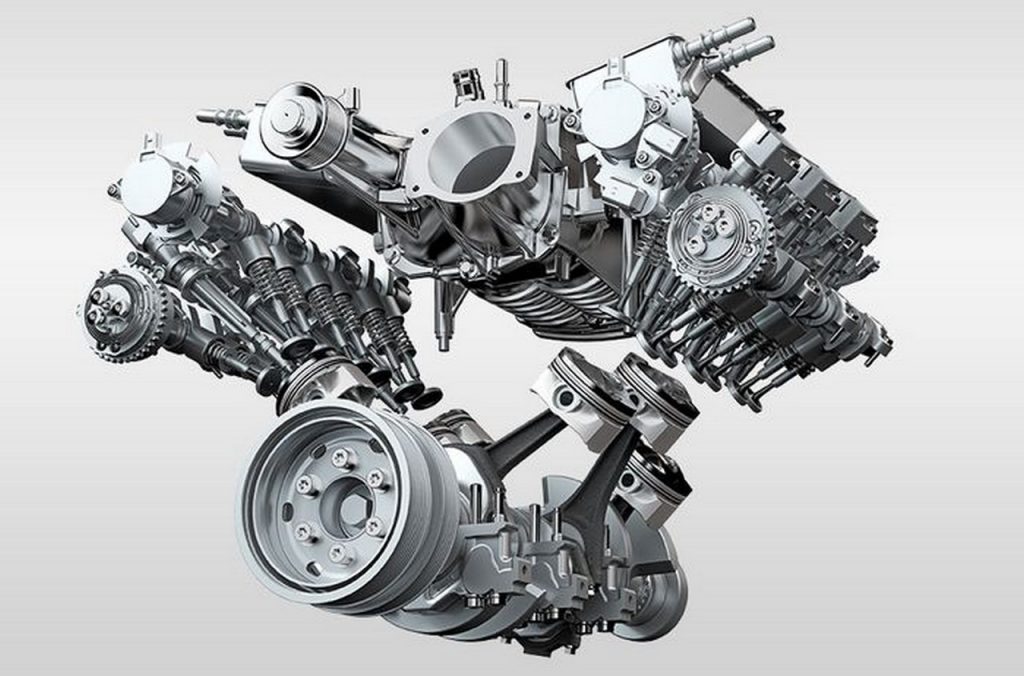

A practical example that can explain how a volumetric compressor works is a bicycle pump: air is sucked into a cylinder (the pump) and compressed by a piston, hence the term piston compression. Piston compressors work in exactly the same way as a bicycle pump, except that in this case the piston is represented by a connecting rod and a rotating crankshaft.

FURTHER INFORMATION: The piston compressor

In dynamic compressors, the pressure increases as gas or air flows inside them. The elements are “moved” by the driving force of the impeller and are pushed at maximum speed until the diffuser slows them down, producing static pressure. The difference between axial and radial dynamic compressors lies in the direction of the air or gas flow. Finally, unlike volumetric compressors, in dynamic compressors a small variation in pressure causes a large variation in flow rate.

This last aspect helps us to better understand the macro difference between turbochargers (dynamic compressors) and volumetric compressors:

- the former are variable flow and pressure compressors and are used to achieve high air flow rates

- the latter are constant flow and variable pressure and are suitable for providing high pressure ratios even at low speeds.

Riem Italy specializes in the production and distribution of volumetric compressors (piston compressors, screw compressors, etc.) and turbochargers. We design solutions for medium and large plants and have many operating sites around the world.

If you would like to learn more about Riem Italy’s volumetric and dynamic compression products, take a look at our services: Riem Italy services