Vacuum Pump Solutions for the Pulp and Paper Industry

Giugno 26, 2017

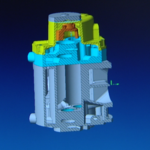

One of the fundamental parameters for tissue paper production machines—and for the plant in general—is undoubtedly efficiency. For this reason, machines have been developed with new technologies for vacuum pumps, capable not only of guaranteeing top production, but also energy savings with optimized efficiency and performance and environmental compatibility. Vacuum pumps are the part of the plant that needs to be addressed in order to maximize cost containment, precisely because they require more energy than other components to operate efficiently. The well-known company Atlas Copco has therefore developed a solution based on the use of low-consumption screw pumps equipped with inverters. Let’s take a closer look at how these pumps work. First of all, these are single-stage, lubricated screw pumps that are cooled by air. The machines and all their parts are assembled on a common base that does not need to be anchored to the ground. Simple installation meets affordability! But how is energy savings achieved? To promote significant energy savings (up to 50% less than conventional technologies), these machines are equipped with VSD+, i.e., variable speed drive. This ensures that the minimum flow required is delivered, corresponding to the vacuum level at the required speed. Therefore, there is no waste. In addition, these Atlas Copco vacuum pumps are very quiet, operating at an average noise level of only 70dB. Vibration levels are almost non-existent, which means that the pumps can be installed close to the point of use without the need for any special anchoring. Ultimately, this new technology from Atlas Copco for the paper industry is highly efficient (both in terms of production and energy), partly because it is developed by working on the applications of partner companies and developing ad hoc projects for customers.