Are Oil-Injected Compressors Sustainable?

Maggio 23, 2017

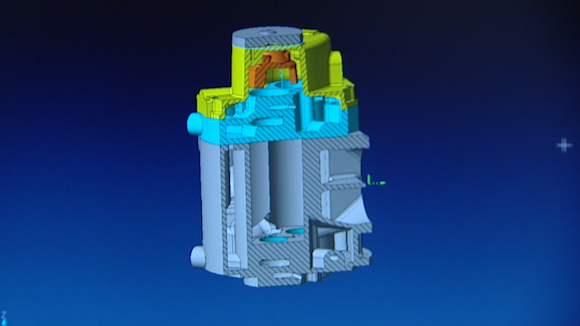

How can an oil-injected compressor be defined as sustainable? Naturally, by conveying and applying the concept of ‘sustainability’ throughout the compressor’s entire life cycle. First and foremost, this starts with the conception and design, then moves on to the production process and finally to distribution: the concept of sustainability is conveyed throughout the entire value chain. The use of recyclable components and materials, the adoption of high-efficiency parts, innovative assembly methods, and high performance combined with reduced energy consumption are certainly capable of significantly minimizing the impact on environmental resources. Atlas Copco was the first company to introduce variable speed technology to the world of compressed air. It is the world’s leading environmentally friendly industry. The US magazine Newsweek analyzed the world’s top 500 publicly traded companies and, based on parameters such as energy and water use, greenhouse gas emissions, and waste disposal, Atlas Copco ranked eleventh in the world and first in the industrial sector. Efficiency, reliability, and sustainability are therefore the main characteristics of Atlas Copco. These innovative features have been incorporated into the VSD+ range, which represents a quantum leap in terms of efficiency, reduction in compressor life cycle costs, and environmental sustainability. Just think that a standard compressor from the VSD range can achieve an average energy saving of 35% more than normal fixed speed technology!