Centrifugal Compressor Overhaul

Giugno 19, 2017

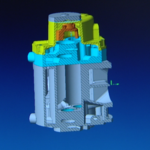

Unfortunately, a complete overhaul of a centrifugal compressor requires a fairly long period of downtime for the company. This is especially true when it comes to large machines. For this reason, new solutions need to be found for this process, which involves close collaboration between the manufacturer and the users. First of all, it is important to consider that the operating life of centrifugal compressors, or at least most of them, can exceed 40 years of service. Unfortunately, however, even though these machines have a fairly long life, forced interruptions in operation can occur more often than one might imagine. This is certainly not determined by maintenance, even if it is carried out routinely, carefully, and at regular intervals. In fact, maintenance is not always sufficient to ensure the perfect efficiency and operation of centrifugal compressors. Field servicing is a task that must be planned very meticulously, requiring planning that also includes the costs of any spare parts, labor, various equipment, and finally, sufficiently large spaces to allow service technicians to work safely. These costs are not always easy to predict. During such overhauls, the machine may be out of service for up to two weeks, and in the case of very large machines, this time may be extended to up to four weeks. Finally, another factor to take into account is any unforeseen events or unpleasant surprises that can lead to a significant increase in costs and time. One process that speeds up the overhaul of centrifugal compressors is the ‘Air-end Exchange’. The air-end is the part of the machine where the compression process takes place. Let’s take a closer look at what this Air-end Exchange consists of and how it can significantly affect the overhaul process: in practice, only this component of the compressor is replaced immediately. This allows the machine to remain operational while the rest is overhauled. As you can imagine, this overhaul technique significantly reduces machine downtime and makes it much easier to keep the cost of the intervention down.